One of the biggest decisions business leaders need to make when starting out on the introduction of a new product is whether to invest in automated test. The cost of setting up an automated test system, while having come down in recent years, is still a significant investment.Opposition to introducing automated test equipment may also come from within your organization as some existing manual test personnel may feel that their jobs are threatened by bringing in new technology. This perceived threat can often be turned around when they realize that the mundane parts of their jobs will be replaced by more exciting roles where they can add more value to the business. Handled correctly, this situation can be turned into a positive experience for all involved.

How to decide which strategy (manual, semi-automated or automated test) is most suitable for any given situation?

A number of questions need to be answered. Is your product low cost? Will it be produced in high volume? Is it high value? Is it complex or relatively simple to test? Is it mission-critical for the end customer? Do you need to test 100% of produced units or can you test only a small percentage? Your answers to these questions will enable you to make better decisions about whether automated test is a strategy you need to introduce.

For companies manufacturing low-cost and simple electronic products, automated test is essential to keep the costs of manufacture and test down. In these cases, having an operator test every product by hand is far too expensive.

Where the product is complex or of high value, it often makes sense to automate testing due to the high cost of specialized technician labor needed to test the product complexity. High-value products often have customers who expect high levels of testing and documented processes to ensure consistent quality.

For mission-critical products, high quality and repeat testing are crucial during all stages of production. Testing should be performed at every level of assembly, from the testing of individual PCBs, through sub-system test, and finally to functional acceptance test. Failure in the field for these types of products (i.e., the cost of bad quality) is far more expensive than comprehensive testing.

The Financial Justification of Automated Test

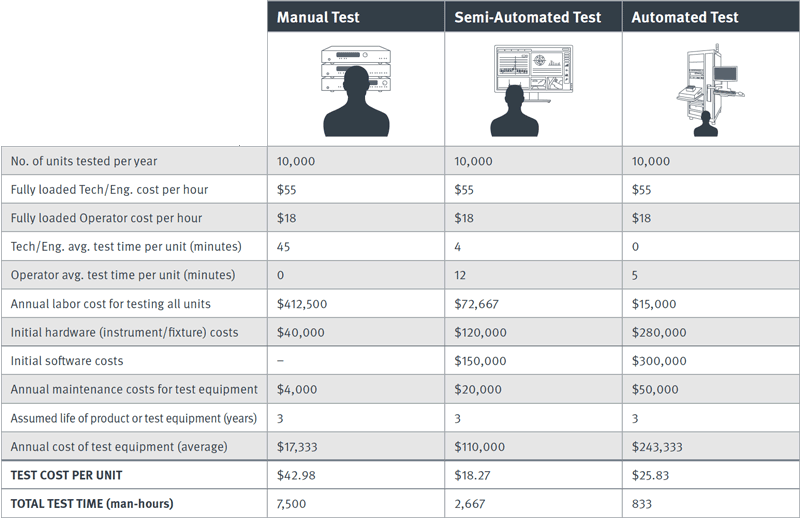

To better understand, and thus justify, the differences in the test processes, it is helpful to apply an example of a typical test scenario. In the example scenario described below, a product that needs to be tested is broken down by potential cost per test for each of the three test processes (manual, semi-automated or automated test).

The critical calculations related to deciding on the best strategy are test time, operator costs, equipment costs, and engineering development (i.e., software design) needed. The example assumes a product line that builds 10,000 units per year according to the estimated fixed costs, development costs, and test times. This information is used to calculate the test costs per unit.

You will see that the critical expense in this example is the test time. As it decreases, the cost per test decreases dramatically. With manual test, operator costs are higher as the level of competence needs to be higher. A trained test technician is required to perform the test. This is not the case with the semi-automated or fully automated test scenarios where a less-skilled operator can be used. (In these cases, the operator could potentially work with multiple testers at the same time, but this multiplexing assumption is not used in the calculations.)

The example presented in the above table provides a guide for calculating different test-type scenarios. In this case, due to unit volume (10,000 per year), it justifies moving from manual test to semi-automated test but not moving to fully automated test. That’s because the volume is high enough to justify some form of automation in order to significantly reduce labor costs, but the volume isn’t high enough to justify the more expensive costs of full automation.

Successful product testing is critical to quality, but there is a cost of good quality, and deciding whether product testing should be manual or automated is a decision that affects the cost of good quality. There are several factors to consider when making these decisions, as well as the trends and modern best practices related to automated test.