Honk if you Love the Electric Bus

Electric buses are coming in hot for a world of reasons, and they are all good. Cities are making major investments in them with the help of government initiatives. With their reduction of carbon emissions combined with their impressive performance and drop in battery prices (and noise), electric buses are an obvious step into the future. They will certainly be zooming (quietly) into your public transportation and school bus fleet if they aren’t already there!

Get on the e-Bus!

With the price of gas these days, the transition into electric buses can’t come fast enough. The wheels are certainly in motion around the world, and the growth won’t slow down for a while.

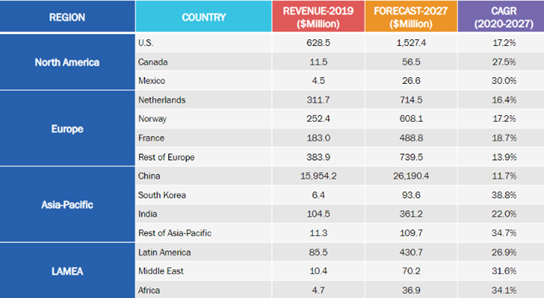

Forecasted Growth of Electric Vehicle Sales by Region - Source: Allied Market Research

This is extremely positive. For years people have been encouraged to take buses instead of cars for the smaller CO₂ footprint they leave compared to cars. Especially when you consider these buses will be running regardless of whether there are people on them. That said, less emissions are good, but none is better. Knowing that maintaining an Internal Combustion Engine (ICE) will be soon more expensive than investing into e-Buses, it’s a bit of a no-brainer for everyone involved.

The Money in Batteries

Not only are ICE buses becoming more expensive to maintain, but electric bus components are becoming cheaper. The battery of any electric vehicle is usually the component that hikes up the price. It used to contribute 30-50% to the final cost of the entire bus!

Thanks to the combination of major innovations in EV and global component shortages, the sales of lithium-ion battery packs and cells hit a new high and a shockingly low cost. Between 2010 and 2021, costs went down by almost 90%.

The Cost of an e-Bus

The challenges electric buses face are real, but not insurmountable. As things stand today, they are still more expensive to manufacture compared to ICE equivalents. Mass manufacturing is just ramping up. China was leading the pack and started bringing in e-Buses early, followed by Europe in 2019. By the end of 2021, countries like India, the United States, Canada and others grew their e-fleets significantly though China still accounts for 98% of the world’s total. At the end of the day, the demand is only going up and once initial investments are, manufacturing costs will decrease.

Getting Electric Buses Powered Up

Like with any electric vehicle, range anxiety is a real thing. ICE buses are set. They take fuel and places that deliver fuel are readily available. The infrastructure to support electric vehicles including buses is not yet where it needs to be completely rid of the gas guzzlers. The range of a battery will depend on a number of factors, including:

- The bigger the battery, the longer the range.

- The heavier the load, the more power will be consumed.

- The colder the weather, the worse battery performance will be.

- The more difficult the terrain, the more the battery will drain.

- And many, many more.

Speed, the number of stops, road conditions and others all come into play. With large populations relying on buses for their day to day, it is important they can reach their destination.

|

The way to travel moving forward has officially shifted to e-Mobility. Manufacturers, cities, governments, and people are doing their part to contribute to the future of travel. It is clear, everyone simply needs to get on the bus. For questions or advice on e-Mobility test processes, please contact Averna. |

|

Electro mobility (or e-Mobility) represents the concept of using electric powertrain technologies, in-vehicle information, and communication technologies and connected infrastructures to enable the electric propulsion of vehicles and fleets. |

You may also be interested in…

The key to keeping costs low when testing EV power electronics is reusability. See how our end-of-line test platform fits on your manufacturing floor.

The key to keeping costs low when testing EV power electronics is reusability. See how our end-of-line test platform fits on your manufacturing floor.

Get in touch with our experts or navigate through our resource center.