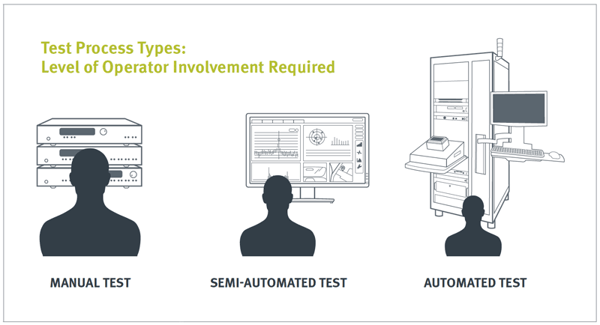

Successful product testing is critical to quality and involves many factors, one of the most important of which is this: when should manual testing be used and when would automated testing be better? This is a decision that can have a big impact on a company’s bottom line and, as such, always needs to be weighed carefully.

Manual testing is traditionally used when there is a simple process in place and labor costs are low. Some companies employ operators who sit in front of test equipment, carefully observing the instrumentation and writing down their test results. This type of testing is often used when flexibility is a key factor for research and development departments who are testing new products under development; the ability to change your test process and try different options is better suited to manual than automated testing.

Cost is also a factor. Companies sometimes find it hard to move from a manual to an automated test process because the perceived costs of software development may seem high. However, automated test is now widely used for testing all sorts of electronic products because in reality the cost of test equipment and software tools is actually on the decline. At the same time, higher labor costs worldwide have made manual testing increasingly more expensive.

Automated testing is used across all product types, whether they are high-volume/low-cost or low-volume/high-value products. However, this distinction does play a role in deciding which type of test equipment to use. With high-volume/low-cost products, test times are often critical so saving seconds of product testing time is key when choosing test equipment. With more complex and high-value products, the ability to perform many in-depth tests is most important. As such, the test equipment for high-value products tends to be more sophisticated and costly.

Meanwhile, mission-critical products are often tested multiple times to ensure correct operation. These are products that are frequently used for human protection or to prevent defective functioning where the consequences could be disastrous. This is particularly true in industries such as aerospace, medical, utilities, and defense where any product failures could have large-scale, destructive results. Companies that produce aircraft components or manufacture medical device implants, for example, were early adopters of automated test technology because the difference between their products working well or not could actually make the difference between life and death.

Semi-Automated Test

Manual versus automated testing is not a black or white issue; many companies use other options for their test strategy. Semi-automated testing is a prime example of a good option for products that require some form of configuration during testing.

During semi-automated testing, an operator is present for some or all of the test cycle. The product is usually placed in a jig, which is connected to a computer. During the actual test procedure, a graphical user interface (GUI) displays on the computer screen and guides the operator through those sections of the test procedure that require manual test adjustments to the product. This could be adjusting a potentiometer, for example, or aligning a mechanical part; the computer may be reading a parameter while the operator makes the modifications.

Once the value is within the required range, the computer may then alert the operator that the adjustment has been properly set. The computer will then take over, and the remaining tests will be run automatically. Again, semi-automatic testing is a great compromise solution for testing that is mostly automated, but may require some manual adjustments at certain points.

In the end, it is up to each company to decide what type of testing best suits its products. There is still use for manual testing in certain circumstances, but increasingly, labor costs, efficiency, and declining software prices are making automated testing the option that more and more companies are making for their bottom line. Could this be the right decision for you?