Automation and robotics essentially take the human out of the loop in production environments, which improves repeatability and reduces variability. For example, automation ensures every test procedure, sequence and step is followed precisely for every unit under test (UUT). No two human operators, no matter how well trained, will test exactly the same way at all times. As well, robots can be programmed, for example, for tedious lifecycle tasks such as repeated button-pushing, knob-turning, screen-reading or other kinds of UUT verification that even the most patient operator will tire of quickly.

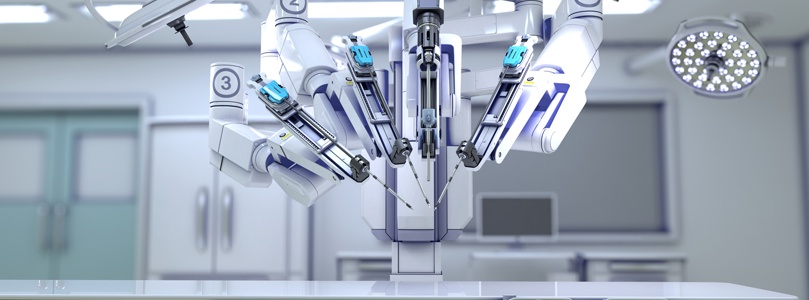

Given the enormous amount of R&D and technological innovation occurring in medtech, it’s unlikely that there will be enough skilled engineers, technicians and managers to handle all the opportunities in the coming years. That means that more robotics will need to be integrated into every aspect of medical device production: from automated assembly and handling to automated testing.

And as robotics-driven production becomes more economical, some business activities that were previously done offshore (typically in Asia) will be brought back to North America (called “onshoring” or “nearshoring”). For many companies, having production and R&D in closer proximity will also reduce communication errors and help solve the challenge of shorter product lifecycles and faster access to their quality data.

To speak with a test & quality expert please visit Averna’s website.