Key Takeaways: What You will Learn About Precision Assembly

► As products become smaller and more complex, precision assembly is critical for performance and reliability in sectors like medical devices, aerospace, electronics, and EVs.► Robotics, optical alignment systems, curing, and laser processes are key for consistent, high-quality assembly in modern manufacturing environments.

► Epoxy resins, UV-curable adhesives, and silicone-based adhesives meet specific needs like thermal resistance, rapid curing, and flexibility without compromising precision.

► Rigorous testing at the final stage of production helps catch defects early, reduce waste, and ensure each product meets exact specifications.

► Averna’s integration of precision technologies into custom solutions helps manufacturers accelerate time-to-market, reduce costs, and maintain high standards, acting as a strategic differentiator.

In today’s high-tech manufacturing landscape, automated assembly and test systems have become a necessity. As products become smaller, smarter, and more complex, the demand for ultra-accurate, repeatable, and reliable assembly processes affects all industries. From medical devices to the smallest consumer electronics, precision assembly ensures that every component fits, functions, and performs as designed.

What is Precision Assembly: Definition

Precision assembly refers to the process of joining components with extremely tight tolerances, often at the micron or sub-micron level. It involves advanced techniques and technologies to ensure that parts are aligned, bonded, and tested with exceptional accuracy.

Precision Assembly in the Manufacturing Process

Precision assembly is typically integrated into the mid-to-late stages of the manufacturing process, where components are brought together to form a final product or subassembly. It often follows machining, molding, and/or fabrication and precedes final testing. The goal is to assemble every part correctly the first time, minimizing rework and maximizing throughput.

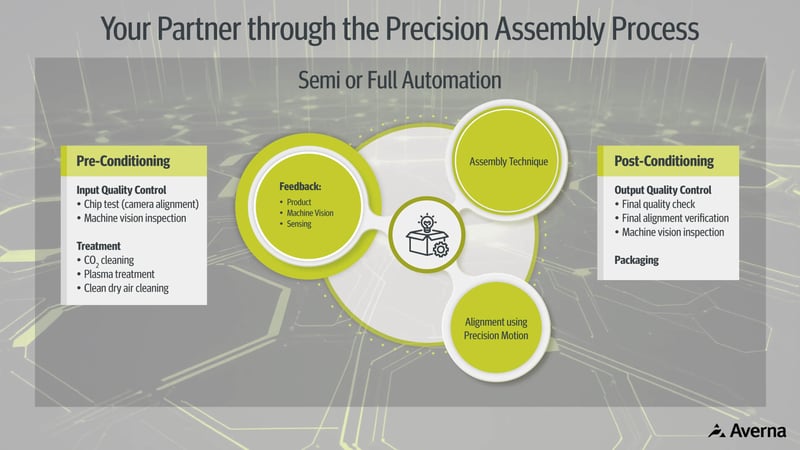

Averna's Precision Assembly Overview

Averna's Precision Assembly Overview

How Does it Work? Technologies & Methods

Modern precision assembly relies on a suite of sophisticated technologies and methods:

Robotics and Automation

Automated systems, including robotic arms, are used to handle delicate components with consistent force and positioning. These systems reduce human error, deliver consistent results and increase production efficiency, especially in high-volume environments. Often, mechatronics engineering services are outsourced to ensure the right solution is in the right place.

Optical Alignment Systems

Vision systems and laser alignment tools help ensure that parts are positioned with micron-level accuracy. These systems can detect misalignments in real time and make automatic adjustments to maintain precision. They offer design flexibility and outperform manual visual inspection.

Advanced Adhesives

Specialized adhesives are used to bond components without introducing stress or distortion. These materials are engineered for specific applications, offering properties like thermal resistance, flexibility, or conductivity. Examples of these adhesives include:

- Epoxy Resins (Strong bonding, thermal stability)

- UV-Curable Adhesives (Rapid curing, ideal for optical applications)

- Silicone-Based Adhesives (Flexible, resistance to temperatures)

Welding

Micro-welding techniques, such as laser or ultrasonic welding, are used to join metal parts with minimal heat-affected zones. This is required to maintain the integrity of sensitive components.

Curing

Curing processes like thermal, UV, or chemical are used to solidify adhesives and coatings. Controlled curing ensures consistent bond strength and durability.

Laser Processes

Lasers are used for accurate cutting, engraving, and welding. They offer non-contact processing, which is ideal for fragile or miniature components.

End of Line Testing for Quality Assurance

Once assembly is complete, rigorous testing ensures that the product meets all specifications. Inline production testing may include functional tests, visual inspections, and automated measurements to catch defects before shipping. End-of-line test platforms are a good solution for IP reuse to lower NRE fees.

Challenges in Precision Assembly

Despite its advantages, precision assembly comes with its own set of challenges:

- Tight tolerances require highly controlled environments and equipment.

- Material variability can affect bonding and alignment.

- Miniaturization increases the difficulty of handling and assembling parts.

- Cost and complexity of automation and quality control systems will vary depending on the application.

- Skilled labor is often needed to oversee and maintain precision systems and can be difficult to find.

Which Industries Need Precision Assembly

Precision assembly is critical in industries where performance, safety, and reliability are non-negotiable:

- Medical Devices & Life Sciences: Surgical instruments, implants, and other devices require sterile, precise, and biocompatible assembly.

- Aerospace & Defense: Avionics and propulsion systems must withstand extreme conditions and operate without error.

- Consumer Electronics & Semiconductors: Optics, sensors, and microchips demand ultra-precise placement and bonding.

- Automotive & EVs: Motors, batteries, and safety systems rely on precision for efficiency, durability, and compliance with safety standards.

Precision Assembly as a Competitive Advantage with Averna

Averna understands precision assembly is a strategic advantage. By integrating advanced technologies like robotics, optical alignment, and end-of-line testing into custom manufacturing solutions, Averna helps clients achieve unmatched accuracy, repeatability, and speed for medical device testing, connected device testing, aerospace and defense and more.

This level of precision enables manufacturers to reduce waste, accelerate time-to-market, and meet stringent quality standards. Whether it’s micron-level precision of sensors or high-voltage EV components, Averna’s expertise ensures that every product is built to perform.

Discover how Averna can integrate precision assembly and testing into your production line. Reach out to our team today!

--

You may also be interested in…

Averna designed and delivered a robust and flexible solution to automatically handle different camera module assemblies while ensuring sub-micron precision and accuracy. The modular system optically verifies the assemblies in all 6 degrees of freedom, performs glue dispensing and UV curing, and removes any contamination. Take a look at the camera module assembly case study!

Get in touch with our experts or navigate through our resource center.