A spotlight has been on the medical industry for some time now. Most people today are waiting for major changes to confront the current state of the world. What isn’t as widely known is the industry was already undergoing some major renovations pre-COVID-19. This is good news.

There are certain fields that always seem to be behind others and Life Sciences was one of those. It was also justified. The repercussions of errors regarding both equipment functionality and patient privacy were not worth rushing into something new. However, over time medical devices and the telemetry technology surrounding them have become reliable and trusted. This resulted in demand for more, and of course, for better devices.

As with any industry, medical device makers need to remain competitive. Products need to evolve with the consumers’ needs. If it’s a hospital purchasing a ventilator or a runner buying a Fitbit, the product must be current. As with most products, this means faster, smaller and more complex.

How are Medical Manufacturers Keeping Up?

With the market and products changing, methodology has been changing with it, particularly with regards to quality. When dealing with the precision and accuracy required in medical, manual inspection simply doesn’t cut it anymore. Individual components can be too small to inspect with the human eye alone and a microscope is very time consuming to focus and re-focus for each part. The exact measurement of the depth of a needle can be imperceptible, as can dust or scratches or any other small defect that may be present. This is in addition to the fact that anything can be subjective to the operator on duty.

If we were talking about a microwave it’s easy to say, what’s the big deal? If there is a defect on your kitchen appliance, you return it with the gratitude that you took the extended warranty. On the other hand, if there is a defect on your pacemaker, it’s a very different story that involves major surgery.

It is also surprising the power a defect can have. Take that pacemaker. The idea is that it will be inside a person’s body for the rest of their life. If there is a scratch, or if 2 components were not bonded together properly, time will make it worse. As years pass, defects grow. What was once small and barely noticeable is now dangerous and being counted on.

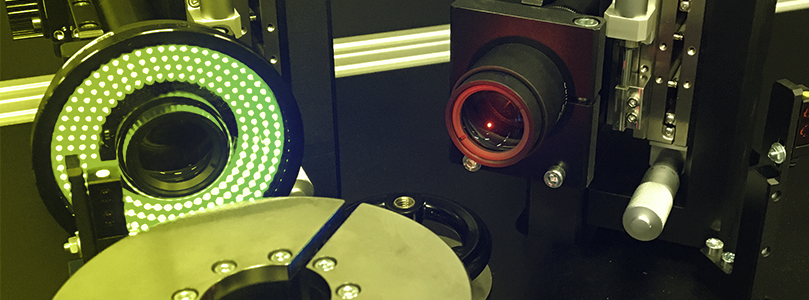

All of this to say, manual inspection is no longer ideal. It is expensive, inconsistent, and unreliable. As such, many medical manufacturers have implemented vision inspection into their manufacturing process. Today, vision is commonly used to accelerate several applications and provide fast, reliable, accurate and repeatable results. These applications include:

1. Feature & Defect Detection

As mentioned above, vision has the ability to find any scratch, crack or blister on critical device surfaces and prevent them from getting out to the field. This also applies to glass vials and rubber stoppers. Today, there is a major concern of a looming vial shortage. Billions of vials, stoppers and plungers will need to be inspected. The only way to get ahead of this will be with vision inspection.

2. Measurement & Calibration

Precise measurements and accurate calibration are key when dealing with anything being inserted into the human body. For example, vision inspection can ensure a needle is inserted correctly into a patient with accurate and repeatable dimensional measurements to micrometer levels. It can also measure the injected dosage of a vaccine by weight measurement with injection volume validation.

3. Identification

Imagine if a medication makes it to your local pharmacy with the wrong label. Machine vision removes this risk by validating products have the correct label, with the right warning symbols, bar codes and serial numbers. It also takes it to the next level by ensuring readability with optical character recognition (OCR) or optical character verification (OCV) image analytics.

4. Physical Alignment & Positioning

Another possibility with vision is accurately positioning products towards each other with 6 degrees of freedom motion solutions. These vision-guided alignment methods outperform traditional product assembly methods in both accuracy and repeatability.

5. Color Analytics

Apply spectral imaging, or other imaging technologies to displays, AR/VR devices and medical imaging instruments where body color accuracy is critical to make judgment calls by medical personnel. A vision system will take images and compare them to set test limits and a device becomes pass/fail. In manual inspection, this decision is determined by a operator’s opinion. It has been proven that results vary from person to person, from morning to afternoon shifts and from Monday to Thursday. Vision inspection delivers consistent, reliable results any time of day.

Another color analytics example is hyper spectral imaging which can be used to distinguish seemingly identical parts from each other. This is commonly used in pharmaceuticals to identify that pills are bottled correctly.

6. Vision Guided Manufacturing

Using robotics and precision motion control, vision systems perform repetitive work with high precision at very high speeds. This includes everything from guiding the assembly process to accurately measure glue beads once assembled, regardless of the part size and position.

This is simply the tip of the iceberg of how machine vision serves the medical industry, and the benefits it offers. And like the medical industry, the technology is also evolving. With the innovations made in vision, what was impossible 5 years ago is now standard and affordable. The key takeaway here is that vision inspection is an organized technology that increases visibility, reliability, and traceability. It is also a major contributor to the medical industry’s evolution and will continue to play a huge role in getting the world through the current pandemic.

Learn how to use Automated Vision Inspection for Medical Applications

Automated vision inspection is the best way to ensure perfect products and fast compliance for the medical industry. There are several different methods it is being used to help manufacturers around the world and we are ready to show you how:

For more information, you can watch this webinar in full or for any quality questions, please contact Averna.

You may also be interested in...

Get in touch with our experts or navigate through our resource center.

Are you thinking about test instead of product development? BPO may be the answer!

Are you thinking about test instead of product development? BPO may be the answer!