Notes from a Test Integrator

The PXI is the whole package for automation and measurement. Combining high performance in a low-cost deployment platform, it has become one of the most common instrumentation tools on the market today. These systems are used for test in communications, manufacturing, and industrial monitoring in a variety of high-tech industries like consumer electronics testing, medical device testing, automotive test solutions and more. They are commonly found in either manufacturing or R&D and now is the right time to get to know the PXI a little better.

ABCs of the PXI from NI (National Instruments)

What does PXI Stand for?

PXI stands for PCI (Peripheral Component Interconnect) eXtensions for Instrumentation. It is a PC-based, software-defined platform that provides power, cooling, and communication to support many modules in one enclosure. It is rugged and flexible and can be tailored for most automated test equipment. The PXI is an open standard, which means any vendor can build a PXI. The platform is governed by the PXI Systems Alliance (PXISA) and they have defined the hardware, mechanical, electrical, and software specifications.

What Makes Up a PXI System?

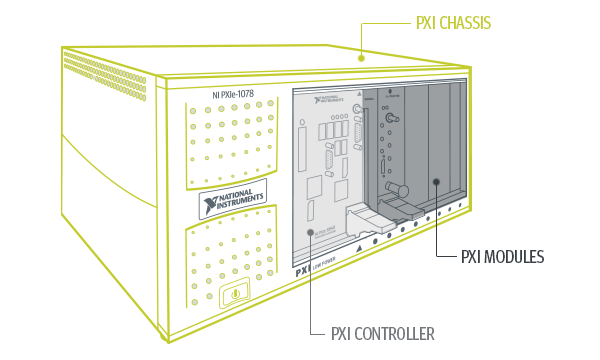

A PXI system is made of three key components: a chassis, a controller, and peripheral modules.

To explain this deliciously:

PXI Chassis

The PXI chassis is the container housing all the modules in built-in slots. The number of slots in each chassis vary, depending on the model. They are available with different options to accommodate different levels of complexity and provide the necessary power, communication and cooling for the demanding modules. This is the cake pan that will go in the oven with all the ingredients mixed in together.PXI Controller

The PXI controller is not just a clever name. It is everything you need to run your system. It is a high-performance computer solution which includes an integrated CPU, a hard drive, RAM, an Ethernet connection, and more. Essentially, they are the flour, eggs and sugar to the test and measurement dessert. Controllers can either be embedded in the system or accessed remotely.

PXI Modules

Lastly, it’s the PXI modules that make the system unique. These provide the flexibility needed to adapt to the application at hand. They interface to bus standards, are responsible for data acquisition, trigger and synchronize different devices, create, and direct signals, and take measurements. These are the flavor component in the measurement and automation recipe. A potent extract, if you will.

PXI's use bus systems for the flexibility they offer regarding the ability to control the different instrumentation. This is carried along the PXI backplane, linking the PXI bus to each card and providing power to the entire system.

What is the difference between PXI and SCXI?

PXI and SCXI (Switch, Control, and Measurement Interface) are both modular platforms used for flexible testing but are built differently and used for different purposes.

PXIs are designed for high-performance regarding demanding measurement and automation tasks. Consider those requiring high data throughput, precise timing synchronization, and powerful processing capabilities.

SCXIs, proprietary to NI, are recognized for signal conditioning and a large channel count I/O. They are designed to provide robust signal conditioning (amplification, filtering, isolation) and to expand the I/O capabilities of a data acquisition system (DAQ).

PXIs are based on the PCI and PCI Express bus standards, with high-speed communication between modules and the controller. The chassis is modular and compact with multiple slots for plug-in modules and has a high-performance backplane and embedded controller.

SCXIs generally use a rack-and-stack architecture with modules housed in separate enclosures that fit into standard 19-inch racks. They rely on a proprietary SCXIbus for inter-module communication and signal routing and are typically controlled by an external DAQ device connected via cables.

Timing is Everything

PXI systems are often the heart of dedicated off-the-shelf test equipment, like Averna's RF record and playback system, the AST-1000 and other RF test and measurement applications. Their architecture allows for the synchronization of measurements across many modules or many chassis with integrated timing and synchronization features. A typical model will have a dedicated 10 MHz system reference clock (which can be upgraded), a PXI trigger, a star trigger, and internal bus communication from slot-to-slot. These signals are dedicated for timing and do not affect the overall communication architecture.

Why Use PXI: Advantages in Test and Measurement Environments

The PXI package delivers accuracy while remaining scalable, flexible, and powerful. It is no surprise that they are the answer to test and measurement’s most complex challenges. It offers high bandwidth and data rates with precise timing and synchronization capabilities. There is a wide range of instrumentation modules available (oscilloscopes, function generators, digitizers, data acquisition, etc.) and is perfect for complex and high-speed applications.

The AST-1000: High-Performance PXI Test Equipment for RF Recording and Playback

Featuring Averna’s leading RF and test expertise, the software-defined AST-1000 leverages NI's PXI and is powered by the NI VST and LabVIEW. It can generate all common radio signals (including AM/FM, DAB, DRM, HD Radio, and Sirius/XM), digital video signals (including ATSC, CMMB, DVB-T2, and ISDB), as well as simulate all common GNSS (including BeiDou, Galileo, GLONASS, GPS, and QZSS) and connectivity signals.

To learn more about automated test and measurement systems and how to leverage PXI, please contact Averna.

You may also be interested in…

PXI is powerful. But the AST-1000 makes it unstoppable! Explore what’s possible with PXI-powered RF testing. See what it can do!

Get in touch with our experts or navigate through our resource center.